Polypropylene Fiber Reinforced Concrete PFRC

Writer: admin Time:2023-11-23 20:42 Browse:

Polypropylene Fiber Reinforced Concrete (PFRC) is a concrete material reinforced with polypropylene fibers, which can provide increased crack resistance, strength, and durability of the material. This article will provide a detailed introduction to PFRC from various aspects such as its definition, performance, preparation methods, and application scope.

1. Definition and characteristics of PFRC

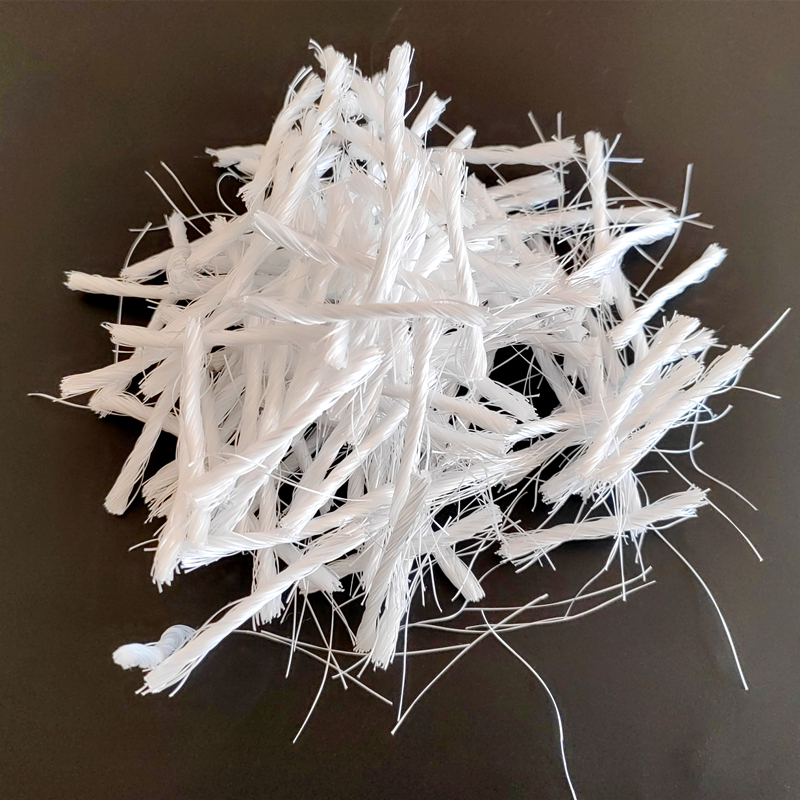

PFRC is a composite material that incorporates polypropylene fibers FD300T into concrete to enhance its performance. Polypropylene fiber is a material with high strength, high modulus, and low density, which has high durability. PFRC has the following main characteristics:

1) Crack resistance: The addition of polypropylene fibers can effectively suppress the expansion of cracks in concrete and improve its crack resistance.

2) Strength enhancement: The introduction of polypropylene fibers can improve the flexural, compressive, and tensile strength of concrete.

3) Durability: Polypropylene fibers can improve the freeze-thaw resistance, durability, and chemical corrosion resistance of concrete.

2. Performance of PFRC

PFRC exhibits excellent performance in terms of mechanical, physical, and durability properties:

1) Mechanical properties: PFRC has excellent performance in crack resistance, compressive strength, tensile strength, and freeze-thaw resistance.

2) Physical properties: PFRC has good durability, toughness, and wear resistance.

3) Durability: PFRC can maintain good physical and mechanical properties under harsh environmental conditions.

3. Preparation method of PFRC

The preparation method of PFRC usually includes the following steps:

1) Material preparation: Prepare an appropriate amount of cement, sand, stones, and polypropylene fibers.

2) Mixing: Add cement, sand, stones, and polypropylene fibers in a certain proportion to the concrete mixer for thorough mixing.

3) Pouring: Pour the concrete into the pre prepared mold to ensure its compactness.

4) Curing: Properly curing the poured PFRC to ensure its good hardening.

4. Application scope of PFRC

PFRC is widely used in the construction and engineering fields due to its excellent performance:

1) Roads and Bridges: PFRC is used for structures such as pavements and bridges, which can improve their crack resistance and durability.

2) Buildings and residential buildings: PFRC is used for structural reinforcement of buildings and residential buildings to enhance their seismic and crack resistance performance.

3) Hydraulic engineering: PFRC is used in hydraulic engineering such as dams and water pipes, which can improve its permeability and durability.

4) Underground engineering: PFRC is used for the construction of underground structures to improve their crack resistance and durability.

Summary:

PFRC is a concrete material reinforced by the addition of polypropylene fibers, which has superior crack resistance, strength, and durability. It has broad application prospects in the fields of architecture and engineering. In order to better leverage the advantages of PFRC, further research is needed on its preparation process, performance, and application, in order to promote its widespread application in practical engineering.