How to Work PP fiber in Concrete

Writer: admin Time:2025-01-27 10:06 Browse:

How does polypropylene fiber work in concrete?

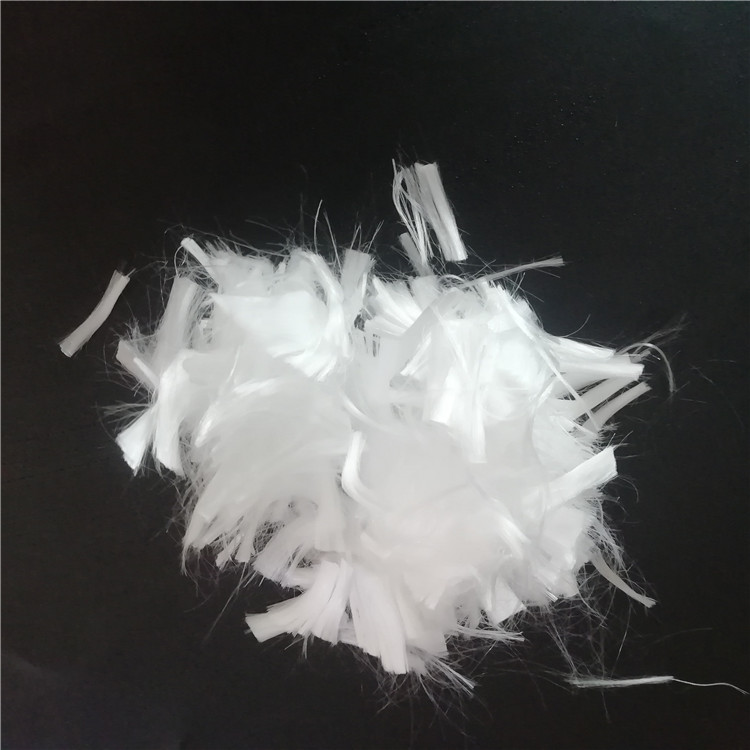

Polypropylene fiber as reinforced concrete fiber is widely used in road and bridge, dam, industrial floor, airport runway and other projects. There are many kinds of polypropylene fibers from the shape, such as mesh fiber, coarse fiber, bundle fiber, hybrid fiber, flat fiber and microfiber. With the use amount and shape of various fibers are different, but most of them are similar, mainly to strengthen concrete, resist the generation of cracks, increase the durability and service life of the project.

How does polypropylene fiber work in concrete? What's the point?

First of all, after the fiber is evenly mixed with the aggregate, it will randomly disperse into the concrete. At this time, the fiber monofilament interweaves with each other and the direction is irregular. After the fiber is solidified with the concrete, it will travel a multi-directional support system. When the concrete is caused by temperature change, water loss, plastic change, etc., the interaction between fibers, different fibers bear and disperse the force of cracking, which can effectively prevent the cracking of concrete products. However, after a long-term experiment and summary, polypropylene monofilament fiber and reticular fiber have obvious effect on the cracks of fresh concrete, but the effect of polypropylene coarse fiber is most obvious due to the cracks of plastic factors in the later stage. Therefore, in the practical application of crack resistance, micro fiber and coarse fiber are usually combined.

Secondly, the addition of polypropylene fiber can greatly improve the fire resistance of concrete. In a fire, water in concrete is heated to steam. In the liquid phase, the volume of steam is 1100 times larger than that of water. This will produce huge tension in the concrete, leading to concrete cracking. These fibers will melt in a fire and form a matrix in the concrete, allowing water to escape. This helps to increase the tension by closing off the water and keeping the concrete for a longer time.

Through the above analysis, it is not difficult to see that the application of polypropylene fiber really greatly improves the quality and service life of concrete engineering.