Polypropylene fiber chopped VS PP staple fiber

Writer: admin Time:2025-05-26 11:32 Browse:

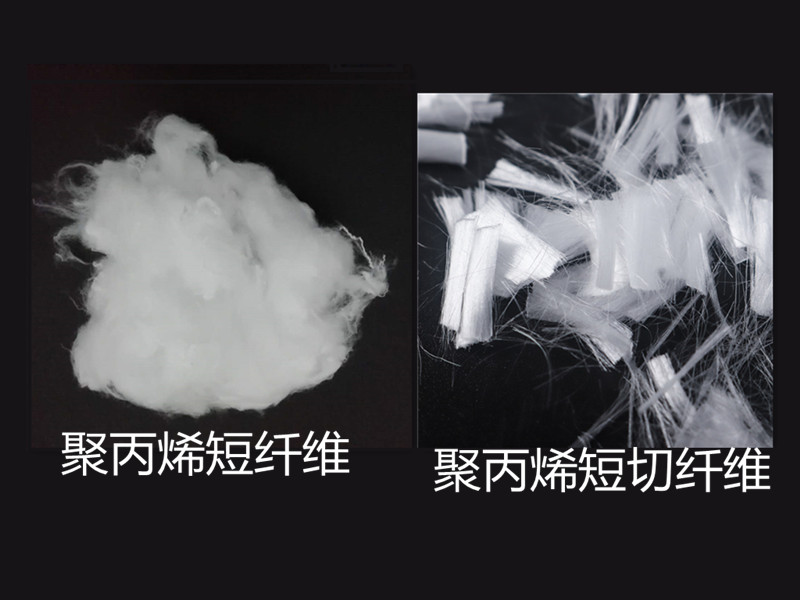

Polypropylene fiber is a general term for all fibers made from polypropylene, including filament, staple fiber, chopped fiber, crude fiber and other products. Long yarn and coarse fiber are easy to distinguish, but the most confusing is short fiber and short cut fiber.

PP staple fiber, also known as PP staple fiber, is a kind of curved fiber, which is usually used in textile, filling, non-woven, knitted, geotextile and other materials. The product specification is mostly from 1.2d-15d, and the length is from 38-110mm. The product has good flexibility, comfortable handle, low strength, large elongation at break and good ductility.

Image : Polypropylene fiber chopped VS PP staple fiber

Polypropylene short cut fiber refers to the short fiber produced by cutting solid filament, with length of 1.5mm, 3mm, 6mm, 12mm, 24mm, 60mm, etc. The fiber is mainly used as reinforcement or toughening materials for concrete, mortar, putty, gypsum and other products. Generally, it has high strength, large modulus and low elongation at break.

Both short fibers and chopped fibers are processed with granular polypropylene resin to ensure the performance and quality of products. In addition, short fibers also have solid, hollow, shaped, blended, etc., and the colors include black, white, red, green and other Pantone colors. The short cut fiber is mainly solid silk, and the color is mostly white.